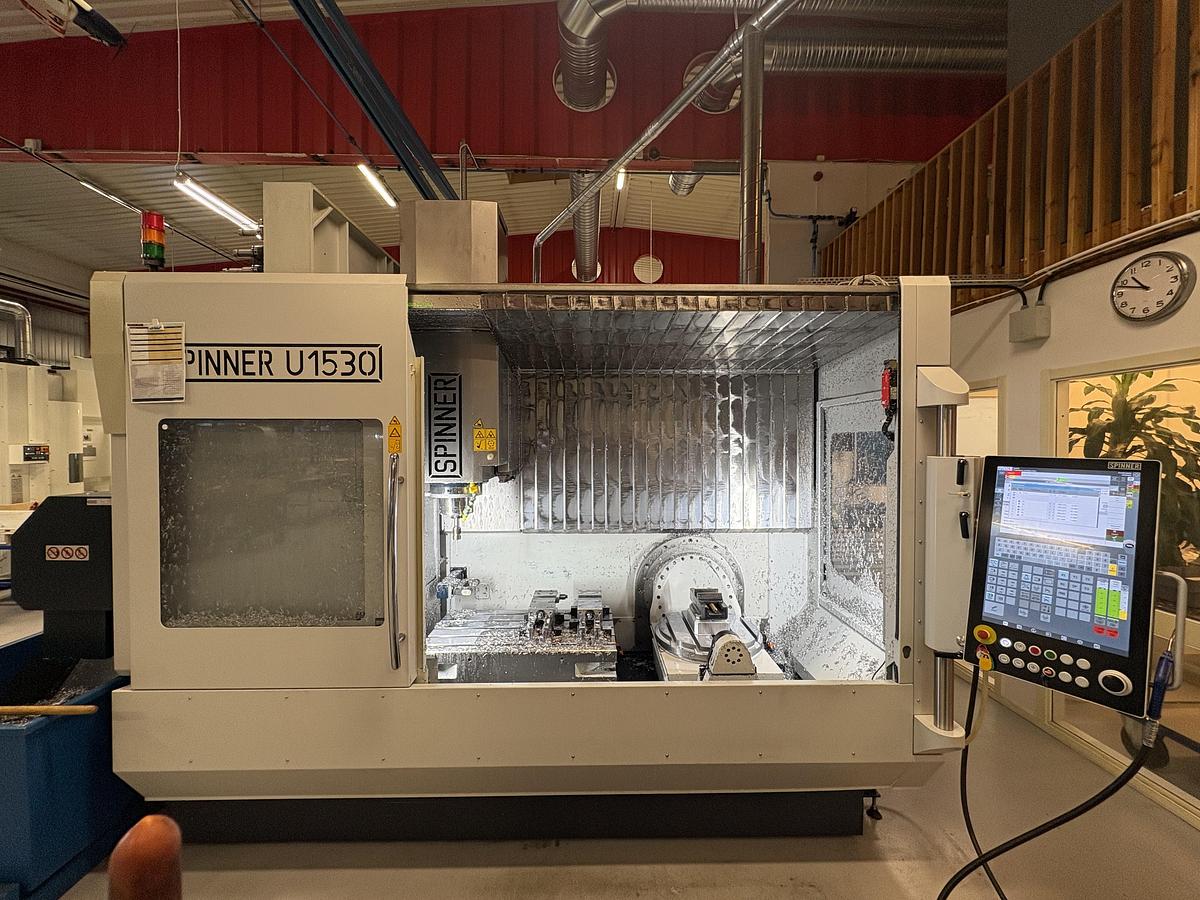

2022 Spinner U5 1530 - Advanced

2022 Spinner U5 1530 - Advanced

Kontakta oss för pris

Plats:Sverige

Beskrivning

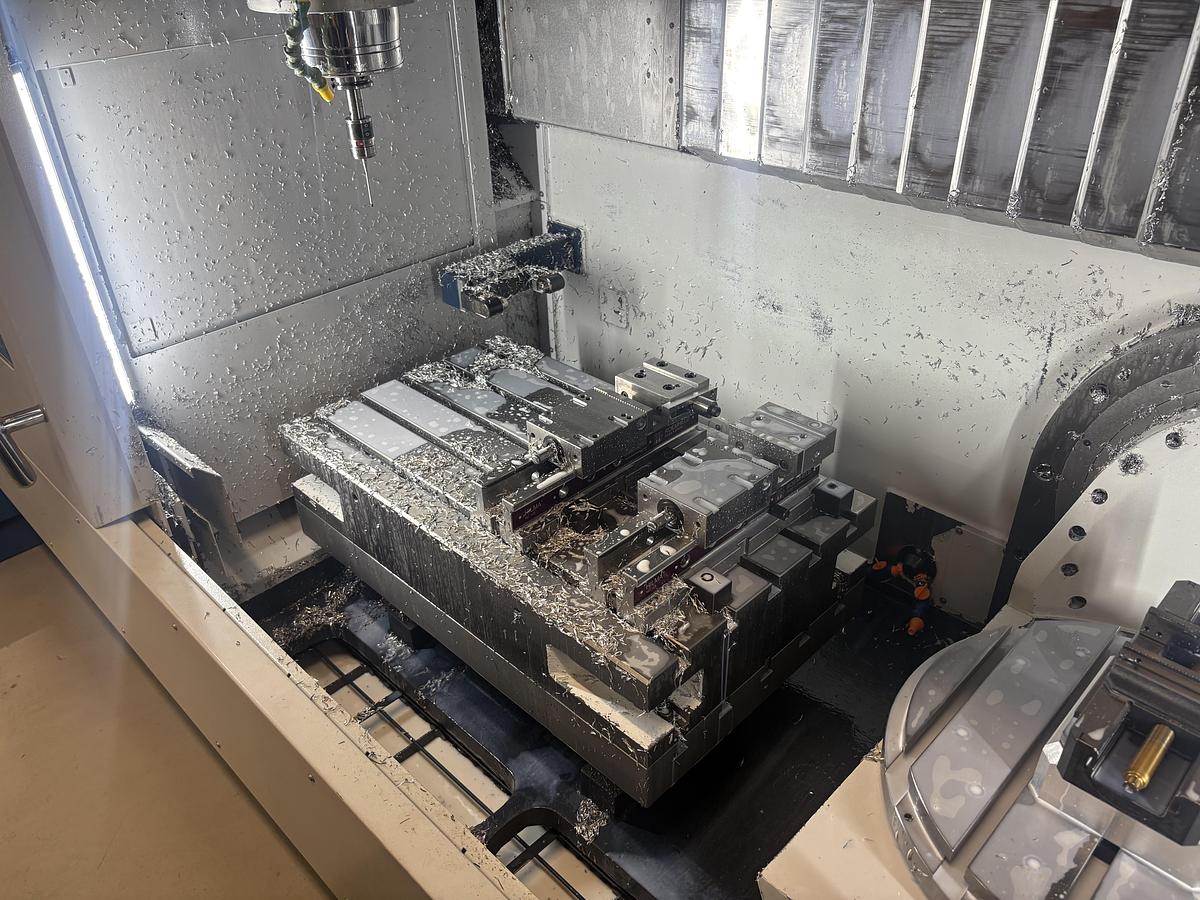

Fully integrated turning and tilting table with counter bearing

Additional fixed table on the left for the first machining side

X-travel of 1,530 mm

High dynamics and speeds of 20,000 rpm

Fully encapsulated work area, separate from the Tool magazine

Good accessibility

Easy to automate with pallets and robots

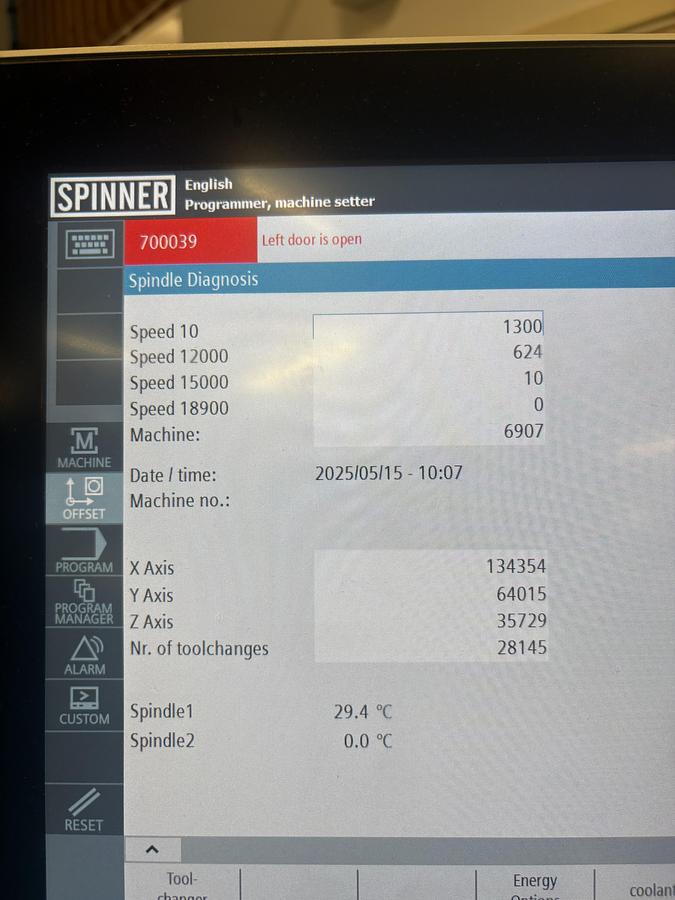

X-axis travel 1.530 mm

Y-axis travel 530 mm

Z-axis travel 465 mm

Rotary table diameter 5th axis 650 mm

Number of tools 54

Spindle speed 20 000rpm

Tool Holder HSK63

U-1530 MACHINE:

Advanced build variant for highest performance level in U5 5-axis version

Strokes X=1530mm, Y=530mm, Z=465mm

Linear guidance in all three axes

Required setup elements on the machine bed for adjustment

Full cladding splash guard + working area light

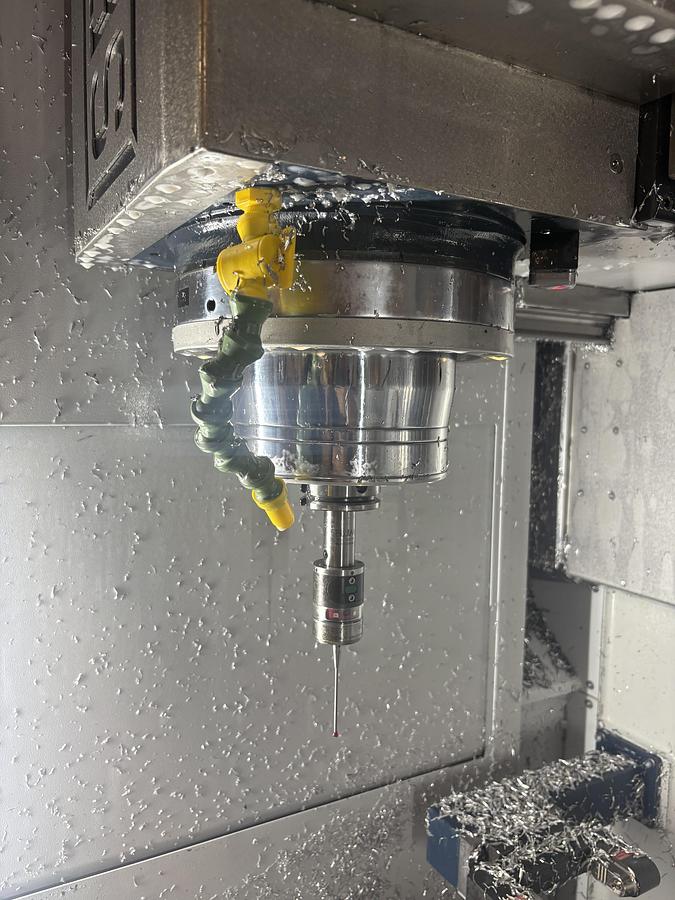

High Precision MILLING SPINDLE:

Up to 20,000 rpm in fit-motor spindle

With direct drive without belt

Liquid cooling

Tool mount on HSK63 spindle

TOOL MAGAZINE:

With 54 tool stations

High-speed intelligent controller version

With fast-running tool chain

Separated from working area by pneumatic flap

U-1530 FIXED TABLE:

With T-slots for fixing workpieces and clamping devices

160mm top plate available for distance table/spindle for tall superstructures and use of tailstock

DIRECT MEASURING SYSTEMS in X/Y/Z-Axis:

For increased positioning accuracy and improved heat transfer

Designed with Heidenhain scales and integrated in control

Version with SIEMENS control with the following features:

Attention: Siemens general conditions for software products are valid

SIEMENS 840D control with features:

New developed: SPINNER-SPIOS 24" Touch Control Panel for 10.4 applications

Ultra-compact design with reduced panel footprint for premium ergonomics

Multitouch layout, colorful flat panel display with Multi touch functionality

Integrated Edge devices for full digitalization

Easy to use and user interface

2-Axis Rotary Tilt Table D=650:

High precision “S” design

Made in Germany with direct measuring systems on both rotary axes

Designed for demanding machining operations

Equipped with high-power gear

Rotary feed for automatic operations and pallet changer

Equipped Features:

Pre-tensioned high-performance brakes in B and C axis

Designed for clamping during emergency stop

High axis stiffness

Increased accuracy in the tilting axis

Heavy-Duty Table:

Max load capacity 650 kg

Tilting force and accuracy designed for serious machining

Hydraulic Brake:

For large rotary table in C-axis

Increased rigidity during machining

Counter-Balance Function in B-axis:

Compensates tilting moment on the rotary table with workpiece force

Enhanced stability during machining

6-Fold Rotary Feed:

Inside the center of the C-axis

6-channel designed for media connection

Max hydraulic pressure of 240 bar or additional exhaust ventilation connections

High-pressure tank:

70 bar capacity with paper band filter for flushing, located centrally through the spindle, stand-alone next to the machine with additional coolant volume, including high-pressure pump and level monitoring.

Additional blower:

Air at headstock for cooling with air instead of liquid.

Compressed air supply:

Supplying via milling spindle, alternatively to coolant high-pressure through spindle.

Rinsing gun:

Installed in the working area for cleaning.

Preparation:

For SPINNER-Blum Touch probe with IR receiver for wireless transmission.

"Advanced Surface"

For optimizing the machining surface.

"Spline Interpolation"

To shorten processing times depending on raw data.

Additional user memory:

2 GB extra on CF card.

Tool correction data sets:

400 sets.

Key functions for probe integration.

Universal chip conveyor with coolant tray U-1530:

Enlarged, L-shaped coolant tank, approx. 200 liters with centrifugal pump (831/min at 8 bar).

Designed for cooling lubricants as emulsion.

Useful even during multi-shift operation.

Suitable for short-chipping workpieces like cast iron or brass.

Manual cleaning/emptying may be needed after chip seizure.

Simultaneous Recording of the Machining Process:

Visual demonstration of real-time machining process recording.

Signal Lamp on Top of the Machine:

Three colors: red, yellow, green.

Red: Machine alarm.

Yellow: End of part program / end of bar / parts pallet empty.

Green: Program is running in automatic mode.

Multi-Axis Interpolation (> 4 axes):

"TRAORI" 5-axis transformations with tool orientation.

5-axis tool length correction.

Oriented MANUAL TOOL RETURN when interrupted.

RCTP function for manual tilting axis movement in manual mode.

Cycle 996 for Kinematic Measurement:

Ensures high accuracy demands on the 5-sided part.

Features:

CNC dialogue

Second language: English

Spinner multi-control-wheel:

Control panel functions integrated into one control element

Handwheel function in jog mode

Feed override in automatic mode

Start button and feed control in single-block setup mode for reprogramming to 0% at the end of the block

Important functions of set-up operation integrated in one control element

ShopMill work step programming

3D simulation:

Of finished parts

Residual material detection:

And machining of contour pockets

DXF-Reader:

Individual license for importing DXF files into the CNC

CNC dialogue – Primary language: Swedish

Second language: English

Spinner multi-control-wheel:

Control panel functions integrated into one control element

Handwheel function in jog mode

Feed override in automatic mode

Start button and feed control in single-block setup mode for reprogramming to 0% at the end of the block

Important functions of set-up operation integrated in one control element

ShopMill work step programming

3D simulation:

Of finished parts

Residual material detection:

And machining of contour pockets

DXF-Reader:

Individual license for importing DXF files into the CNC

Wireless Spindle Switch:

With tool mount suitable for milling spindles.

Laser Blum LC50 Digilog:

For contactless tool measurement with analog signals. Increased accuracy and up to 60% reduction in measurement time versus switching.

LC-Vision Option 3D Tool Control:

For detection and visualization of contour status of cutting edges.

Digilog Option ToolTip-Control:

Searches for radial maximum point on turning and milling tools.

Indirect length control of the tool possible.

Wear compensation by actualization of max point in tool memory.

Highest precision and short measuring duration via an intelligent algorithm.

Temperature-dependent Siemens drive blocking.

Calibration mandrel for laser with tool mount to fit spindle.

Robot flap:

On the right side of the working area, including control unit as access for robot cell or palletizing system.

Universal robot interface:

From manufacturing year 2021, available via a common connector at the electrical cabinet of the machine, with signals such as:

Potential-free safety signals

Standard signals over Profinet, PN-Bus coupler, or RJ45 socket

According to UNIROB-V2021-Manual

Important note:

If external automation systems are not supplied by SPINNER, the CE marking will expire, and the system must be re-certified by the automation partner.

Standard documentation in English:

Includes machine manuals and CNC manuals, supplied digitally. Printed manuals may incur additional charges.

Simplified 3D model:

For working area or configuration.

Postprocessor creation support:

For specific machine types, supplied digitally.

Ring eyelets:

For crane unloading, consisting of 4 pieces, essential for crane transportation.

Standard paint:

Light grey RAL7035 and blue grey RAL5008.

Electrical version as follows:

Operating voltage: 3x400V ±10%

Main frequency: 50Hz (±2%)

TN network (5-wire).

Calibration-ball for kinematic-measure Tailstock

for kinematic measurement

version with magnet fixing system, high-precision-ball inclusive magnet fixing system for adjustment of rotary-axis of 5-axis machines, ball-height mounted on magnet fixing H=237mm suitable for U-series machines.

Tailstock

NTTS-320 adjustable height,

Specifikationer

| Tillverkare | Spinner |

| Modell | U5 1530 - Advanced |

| År | 2022 |

| Skick | Begagnad |

| Lagernummer | 4847 |